How To Repair A Sprung Nib

Yous might exist wondering correct at present. What is neb metallurgy? How does that even bear upon anything? There are only two (or 3) different materials that nibs tin be made of correct? Well, at that place are quite a few different factors that will bear on the writing feel of your pens. Understanding some of these different effects on your pen can allow y'all to tailor your nibs to go some different effects. Whether that's stopping a nib from singing or adding flex to a pen.

This is going to exist a two-part article, the outset 1 this week will encompass the metallurgy and the second next week will embrace the actual shape of the nib.

Flex Flex Flex:

Nibs tin range from hard as a nail Platinum music to the softest wet noodle Waterman #2. So what gives? (literally) Nibs with bounce tin be a pro or a con for different users simply the mechanics that are behind why nibs do what they do are contained in two different factors: the material and the shape. On the surface, this seems obvious just at that place are some important nuances to sympathize if y'all want to experiment with nibs, mayhap making a neb flex or fixing a nib that was bent out of shape or had its tines sprung.

Nakaya music nib, one of the hardest nibs I've ever used.

Mechanics of Materials:

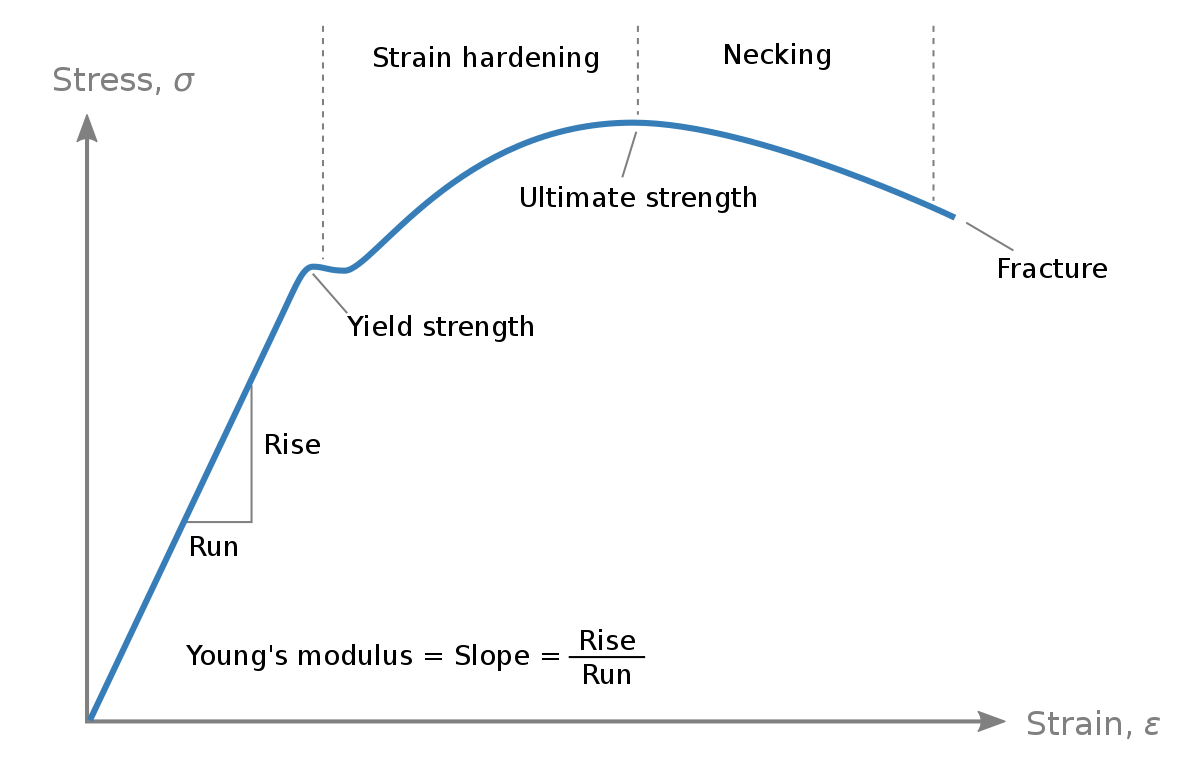

If you are a mechanical engineer y'all have well-nigh definitely been in a class called Mechanics of Materials or something similar (I won't diameter yous with the details or the calculations every bit that might be an article for another day). What you need to know about is the difference between elastic and plastic deformation. I'll use a graph to explain what I mean past this:

Full credit to Wikipedia for this picture.

I'll break this graph downwards into sections to brand it easier to assimilate and I'll tie it to what happens in a neb when yous flex it and then bound the tines. To interruption down some of the terms here "Stress" ways how hard you are pushing or pulling the material. "Strain" is how much the textile stretches equally a issue of the pressure you are putting on it.

The Straight and Narrow:

The showtime section there, which has the straight line that says Run and Rise on it, is the department that encompasses the most normal usage of fountain pen nibs. When you are using a fountain pen nib (fifty-fifty a flex bill) 99% percent of the time you are in this range. In this range, you can have the tines move, only they will bounciness back. This is why it is called elastic deformation. It is like a condom ring, when yous stretch it the ring always comes back to the aforementioned shape that information technology was before.

When making a flex neb your goal is to stay in this range or you will jump the tines. This is where the different materials come into the picture. You desire a cloth that when flexed stays inside of the '"elastic zone". That way when you flex the pen information technology will come back to the shape that it was earlier. Some types of materials are better than others. Metals are very expert at this blazon of elastic deformation hence their use in flex nibs.

This beak has nothing do to with this part its just a absurd looking pecker by Jim Crawford

In terms of materials, you don't desire anything too soft or as well difficult. It's all a balance of making sure that the "rubberband zone" line is both as long and as well flat as possible. The longer that line is the more force you can put on the nib without springing the tines. The flatter the line is the more than flex y'all tin can get without having to push too difficult.

Let'south take this out of an abstract give-and-take of graphs and give a concrete instance of what this ways. Let's have two different extremes to show how we should run into in the middle. The first example is of a ceramic mug. A mug is difficult and no matter how hard you press on the mug information technology won't budge. You tin imagine how making a flex pecker out of ceramic would exist impossible. Information technology's harder than a nail. The ceramic has a steep "rubberband zone" line which means that information technology does not flex fifty-fifty if you put a slap-up deal of force on information technology.

Okay then well, ceramic is mode as well difficult then let's go with something softer. Right? (I know, I know, a bit much with the rhetorical questions)

From Springy to Sprung:

So we want something soft then that nosotros tin can avoid the problems that a ceramic nib would have with non beingness able to flex. So we have to get softer than ceramic. Merely how soft can we become? Metallic is a good idea for a first, it's much softer than ceramic (every bit the astute readers may accept guessed). Just to get to the extremes once more allow'due south say we fabricated a neb of glue (unchewed you sickos).

Chewing gum wouldn't make a adept substitute for a nib for a few reasons, but the master one is that information technology'due south like shooting fish in a barrel to push it out of shape. Information technology'southward also soft, any amount of pressure that you put on it would bend it out of shape. This is what is called plastic deformation and it is the next section of the graph. Information technology's all of the curve from when it says Yield Forcefulness to Fracture. All materials exercise this when you put too much pressure on them, they will bend out of shape. The main thing with chewing gum is that the start "elastic zone" is very curt and therefore it gets to this "plastic zone" without much pressure on the pecker.

This the zone where a nib will be sprung. You lot put likewise much force per unit area on information technology and information technology volition go past rubberband deformation and go directly into plastic deformation. This is the splayed pecker and the aptitude tine that everyone dreads.

So if you are here looking to repair a bent tine at that place is some good news and some bad news that yous have to be aware of before going frontward (also Godspeed). Repairing a bent neb or a sprung tine is a relatively simple matter of bending information technology back into the correct shape. The bad news comes with ii words in the graph above: Strain Hardening.

This is an example of a Parker beak that has some damage. Taking out that damage would be difficult as the damage caused strain hardening.

I don't want to become into a long explanation nigh grain size (mostly because it's kinda boring), and so suffice to say that as you bend metallic information technology becomes harder to bend back considering the metallic becomes brittle. The more it becomes brittle the more likely it is to break. This process is besides referred to equally piece of work hardening. You might accept noticed this when bending a wire or a newspaper prune dorsum and forth. It gets harder and harder until somewhen, it breaks. This means that just because a neb is bent but not croaky doesn't hateful that it can exist saved. Sometimes you will bend dorsum simply sometimes information technology will merely intermission considering of that brittleness. This blazon of fracture brings united states of america to the last part of the graph: Necking and Fracture.

Tearing a Tine:

This terminal section is adequately cocky-explanatory, and then I won't waste too much time on it. Once you get a tear in the beak there isn't very much that you can practice virtually it. Some success stories accept been shown on by John Mottishaw here. He has welded some nibs together quite impressively but I'g not sure to what degree the nibs will be the aforementioned as they were earlier every bit welding also frequently changes the properties of the metal that is being worked on.

The Goldilocks Problem:

This is role of the reason that there are non many good modern flex nibs. Y'all are balancing two things that are fundamentally at odds with each other. A material's ability to bend and a fabric'southward ability to return to its shape. This is what makes the Waterman nibs and then impressive. They can flex very far and come up back to their shape.

I don't subscribe to the idea that this technology is somehow lost and can never be done over again. I just think that modern companies researching to do flex nibs that they would then have to tune and worry about are more than than they want to deal with. It just takes time and possibly someone is experimenting with this technology now that there is a renewed interest in flex.

All that'due south Gold is Gold:

Shifting gears a little here I want to talk about the composition of the metals that we make fountain pen nibs out of. I'll start with gold every bit that is the more than sought-after material.

You most likely already know that pure gold isn't used for fountain pen nibs. Gold (and any nib made out of it) is graded on its purity. 14k, 18k, and 21k are the most prevalent. And as the aureate content gets higher the bill will get softer, this is something that is pretty well known. But then why are the Crewman 21k nibs and then much harder than the 14k Pilot ones? There are a few answers, but 1 that I want to talk most at present is what is called annealing or heat treating.

This is the procedure of making metal harder or softer by heating it or cooling it down. This tin can be washed either rapidly or slowly depending on the effect that you want to go. You might have heard this referred to every bit "rut treating". This process dramatically changes the properties of any metal. It could make the material extremely hard and brittle or very soft and mailable.

Each manufacturer will have their methods for doing these oestrus treatments and thus each of them tin make their nibs harder or softer without having to worry almost the aureate content of their nibs. Then if Sailor wants to have a hard beak only besides wants to have the prestige of offering the highest gilded content nibs they can. And because of the strain hardening that tin occur from forming these nibs, the thinness of the beak doesn't matter. Often the thinner that gold is rolled the harder it is due to that strain/piece of work hardening.

What each company mixes with their gold to make the alloys they get are different likewise. Someone has informed me that the US often uses nickel for alloys which I idea was standard around the world, just obviously, it is illegal in the Eu. The EU manufacturers use palladium instead. This will also alter everything between the ii nibs with the same gold content. I don't know what they apply in Japan. Some alloys volition exist stiffer and some will be softer. Information technology will too change how work hardening affects the nibs likewise.

Other Materials:

Some of what I was talking nearly can be seen in the other two prominent neb-making materials: steel and titanium. Steel is harder than gold (nearly of the time) so it does not bend as easily every bit gilded does, making for a much harder and more than rigid experience. Titanium on the other mitt is different in that it is fairly soft and bounces back (or at to the lowest degree the Bock ones do), but it has the drawback of springing much more hands than either golden or steel. This will vary greatly betwixt unlike types of nibs and different brands. While Jowo nibs have shown themselves to be well suited for making flex nibs it doesn't mean that every steel beak will be.

At that place are many many unlike types of stainless steel and they all have different properties. Stainless steel can become incredibly difficult when treated in a certain fashion and so there are not hard (ha) rules when comparing nibs.

Where the Nib Hits the Newspaper:

Then at this bespeak, I want to give a few examples of what I am talking most when it comes to certain nibs and how these principles employ to them.

Airplane pilot #10 FA Bill

This is (in my stance) the best modern flex that y'all can buy and rivals the vintage flex nibs for softness and flexibility. I would guess that aside from the cutouts (that will exist covered in next week'south commodity) on the Pilot FA the reason for the success of this nib is dependent on metallurgy.

Get-go, the pilot FA beak is a 14k gold bill which all the experts concur will allow for some softness and some snapback that makes it ideal for a flexible neb. The nib is patently and unstamped with patterns and I suspect that this is because the stamping would strain harden the metal and go far less flexible. Both of these will make the pecker meliorate suited for flex than another pen that had the same shape.

Waterman Ideal #ii

This is ane of the greatest nibs of all time. The Waterman #ii can be an amazing wet noodle nib that tin be one of the most responsive nibs always made. Even though smaller nibs are commonly harder to flex this nib can exist extremely soft while holding its shape for over 70 years in some cases.

This particular Waterman has seen ameliorate days.

I don't think that it'due south exactly a mystery what these nibs were made of, as that is easy to decide (it involves vaporizing the pecker and looking at light waves). The difficult affair that makes them hard to replicate is how they were heat treated and how they were stress hardened. If modern manufacturers knew how to practise that nosotros would be able to figure out exactly how to make Waterman #ii vintage flex nibs.

Visconti 23k Pd Nibs

This was a risk to have for Visconti to try and brand a nib out completely new material.

This nib had its fair share of problems with QC but it seems as though they worked well and were very soft. The nibs were soft to a fault and were fairly like shooting fish in a barrel to bend out of shape. Adjusting the tines on these nibs was difficult because any corporeality of small movements and adjustments could make vast changes. This bill would plastically deform very easily and it could sometimes be a trouble for the nibs.

Metallurgy

The metallurgy of nibs is a fascinating thing and well worth looking into farther. I am going to try a few different experiments in making flex nibs and mayhap trying to anneal some nibs and change their properties to make them more than conducive to flexing.

Next calendar week I'll look into how the shape of the nib can affect the writing experience, from how a nib sometimes volition "sing" to how Noodler's altered their music nibs in the Triple Tail to make them better at flexing. I hope you'll take a look at that as well every bit some of the other manufactures that I have up.

Equally ever thank you for taking a wait at my manufactures, if you accept any suggestions for articles or things that you'd like to see as well equally corrections or only general feedback feel free to e-mail me at minabekopens@gmail.com. And if you like what I practice here and desire to back up me you tin head over to my Patreon folio and sign up to be a patron, information technology helps me pay for the fees for keeping this website upwards.

I promise that yous have a great day!

-Minabeko

How To Repair A Sprung Nib,

Source: https://www.minabeko.com/mainarticles/nib-metallurgy-primer

Posted by: mikelgrephersur.blogspot.com

0 Response to "How To Repair A Sprung Nib"

Post a Comment